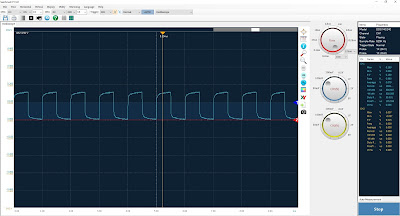

I have finally been able to get the combination of a MSGEQ7 and WS2812 LED strips to work together. The trick was to not use any machine language code. Instead, to access the WS2812 I just used parallel output commands like this:

PORTD= 0xFF; // turn on

PORTD= 0xFF; // delay

PORTD= 0xFF; // delay (Remove for faster processors)

PORTD= bits; // send data

PORTD= bits; // delay

PORTD= bits; // delay

PORTD= bits; // delay

PORTD= bits; // delay

PORTD= 0x00; // Turn off;

Sending the same command over and over just results in a delay.

This setup gives 90 steps to the top. I am missing one LED strip for the needed total of 14. I will add three more strips as soon as they arrive from China.

Here are some links to the videos on YouTube. For some reason they don't embed the videos like they used to? I think they are working now.

This is the code for the right channel only, but blogspot might remove all of the < and > from the code.....

// BOB Davis Enhanced Version for sending data to 8 Parallel WS2812 strings

// Removed Assembler and simplified the code

// Changed to VU meter with MSGEQ7

// PORTD is Digital Pins 0-7 on the Uno change for other boards.

#define PIXEL_PORT PORTD // Port of the pin the pixels are connected to

#define PIXEL_DDR DDRD // Port of the pin the pixels are connected to

// MSGEQ7 pins

#define PIN_STROBE 9

#define PIN_RESET 10

#define PIN_LEFT 4 //analog input

#define PIN_RIGHT 5 //analog input

//band arrays

int left[7];

int right[7];

int col=0;

void readMSGEQ7() { //reset the chip

digitalWrite(PIN_RESET, HIGH);

digitalWrite(PIN_RESET, LOW);

for(int band=0; band < 7; band++) { //loop thru all 7 bands

digitalWrite(PIN_STROBE,LOW); // go to the next band

delayMicroseconds(30); // gather data

left[band] = analogRead(PIN_LEFT); // store left band reading

right[band] = analogRead(PIN_RIGHT); // store right band reading

digitalWrite(PIN_STROBE,HIGH); // reset the strobe pin

}

}

// Actually send the next set of 8 WS2812B encoded bits to the 8 pins.

// The delay timing is for an Arduino UNO.

void sendBitX8( uint8_t bits ) {

PORTD= 0xFF; // turn on

PORTD= 0xFF; // delay

PORTD= 0xFF; // delay (Remove for faster processors)

PORTD= bits; // send data

PORTD= bits; // delay

PORTD= bits; // delay

PORTD= bits; // delay

PORTD= bits; // delay

PORTD= bits; // delay

PORTD= 0x00; // Turn off;

}

// Set default color for letters

int red=1;

int green=1;

int blue=1;

void sendPixelRow( uint8_t row ) {

// Send the bit 8 times down every row, each pixel is 8 bits each for R,G,B

for (int bit=0; bit <8; bit++){

if (green==1)sendBitX8( row );

else sendBitX8( 0x00 ); }

for (int bit=0; bit <8; bit++){

if (red==1)sendBitX8( row );

else sendBitX8( 0x00 ); }

for (int bit=0; bit <8; bit++){

if (blue==1)sendBitX8( row );

else sendBitX8( 0x00 ); }

}

void setup() {

PIXEL_DDR = 0xff; // Set all row pins to output

pinMode(PIN_RESET, OUTPUT); // reset

pinMode(PIN_STROBE, OUTPUT); // strobe

}

void loop() {

red=0;

green=1;

blue=0;

readMSGEQ7(); // collect samples

cli(); // No time for interruptions!

for (int b=1; b > 90; b++){

if (b > 60) {red=1; green=0;}

else {red=0; green=1;}

col=0;

if (right[0]-64 >= b) col=col+1; // Send bytes as VU meter data

if (right[1]-64 >= b) col=col+2; // Send bytes as VU meter data

if (right[2]-64 >= b) col=col+4; // Send bytes as VU meter data

if (right[3]-64 >= b) col=col+8; // Send bytes as VU meter data

if (right[4]-64 >= b) col=col+16; // Send bytes as VU meter data

if (right[5]-64 >= b) col=col+32; // Send bytes as VU meter data

if (right[6]-64 >= b) col=col+64; // Send bytes as VU meter data

sendPixelRow(col);

}

sei(); // interrupts back on

delay (50);

// }

}

90>8>8>8>